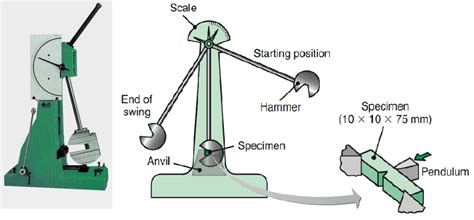

charpy impact test brass|charpy impact test formula : broker Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These . Resultado da 29 de jun. de 2021 · Quer saber se conhece mesmo o Allan? Confira aqui! Home Criar Explorar. Entrar Cadastre-se. Entrar com Google Entrar com .

{plog:ftitle_list}

web19 de dez. de 2023 · Os protagonistas de Um Refugio para o Amor (Foto: Reprodução) Leia agora o resumo da novela Um Refúgio para o Amor (de 18/12 a 19/12/2023) e saiba o que vai acontecer nos próximos capítulos. .

undersized charpy impact test

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These .

quality control test for soft gelatin capsules slideshare

The purpose of this study was to implement dynamic loading under the standardised testing conditions of the Charpy test (AS 1544.2-2017) using a drop tower testing equipment.Overview of materials for Brass, This property data is a summary of similar materials in the Mat database for the category "Brass". Each property range of values reported is minimum and maximum values of appropriate Mat entries. . Charpy Impact, Average value: 47.1 J Grade Count:52; Electrical Resistivity, Average value: 0.00000818 ohm . The basic principle and practical procedure of the Charpy impact test on Different Metal* Apparatus used for test- Testing machine, The test specimen, Scale*.

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus. This test determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch . Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its behavior under sudden loading. This test is crucial in assessing the suitability of materials for applications .charpy impact test brass-Lab Plastic Izod Impact Test Machine Factory Price impact testing machine used to measure plastic, enhance nylon, glass fiber reinforced plastic, ceramic, and cast stone, plastic appliances, insulating materials and nonmetal material impact toughness.This tester can be used for research agencies, universities and . Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2. Unfortunately, while the test, including machine and specimen geometry, has been .For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of .Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized. They were one at a time properly placed within a .

Charpy Test The Charpy test is a good way to measure material toughness. It is useful for materials that exceed the 10.mm (0.394.inches) Charpy height. Specimens can also be made in ¾, and ½ sizes so in theory a 0.20 inch thick specimen can be produced. The Charpy specimen is relatively easy to make and test.The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.A Charpy impact test uses a pendulum to break standardized test samples, and the absorbed energy is measured to assess the material's resistance to sudden loading. 3. The results showed that the aluminum and mild steel samples . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after .

In the charpy impact test we use a test specimen which have a notch at one side of it. Figure 4 — Specimen. . Finally, when comparing the brass and steel V type specimens, the brass one has a .Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type (b)To determine the variation of impact strength of a material with change in temperature Experimental Method:The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

Question: Two brass specimens of the same chemical composition undergo the Charpy impact test. Whereas one of the specimens is tested at room temperature, the other is held in liquid nitrogen prior to testing. In both tests, the hammer (mass 4.5 kg) swung from the same initial height from the ground, before impacting the specimen.An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .By doing this, it is possible to characterize how much energy different materials [with same size] can absorb. Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application. A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force .

42 ENGINEERING 36 MATERIALS SCIENCE CHARPY TEST COMPARATIVE EVALUATIONS STEEL-CR2MOV IMPACT TESTS ENERGY ABSORPTION SHEAR PROPERTIES STEEL-ASTM-A533-B WELDED JOINTS Charpy impact testing verification 2-mm striker 8-mm striker lateral expansion instrumented striker energy percent shear standard .Izod Test Standards: Common Izod impact test methods include ASTM E23 & BS 131 for metals, and ISO 180 & ASTM D256 for plastics. Izod vs Charpy Test Comparison. One of the main differences from Charpy impact is that Izod impact testing is performed in two orientations on the same sample whereas the Charpy test is performed in the same orientation.The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3). Plastic deformation. Permanent deformation of the material when a load is applied, then removed.According to the Charpy impact test results, the third sample having 1000 °C casting temperature had higher breaking energy compared to samples casted at 1200 °C and 1100 °C.

notched charpy impact test

charpy impact testing

quality control tests for soft gelatin capsules

charpy impact tester pdf

webDiscover the most popular 4ThePlayer casinos for 2024! Try the best 4ThePlayer slot games, get a casino bonus, and start playing today!

charpy impact test brass|charpy impact test formula